The DSEE800 is an intelligently design engine control module that provides flexible control, comprehensive monitoring and protection features.

The control module is suitable for use with standard and electronic engines and can handle a wide range of applications including engine driven pumps, compressors, and hydraulic power packs and off highway machinery.

240 mm x 172 mm x 57 mm (9.4” x 6.8” x 2.2”)

8.0 mm (0.3”)

E800-01 – E800 Engine Control Module

220 mm x 160 mm (8.7 ” x 6.3″)

0.88kg

| Key Features | Key Benefits |

|---|---|

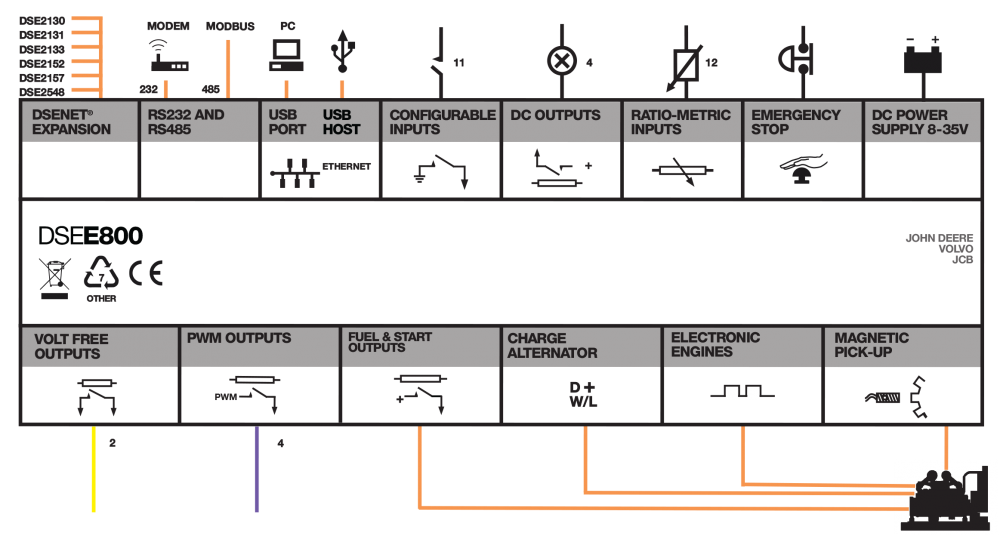

| Configurable digital inputs (11). | Provides multiple installation options. |

| Configurable ratio metric inputs (12). | Provides multiple installation options. |

| Configurable DC outputs (4). | Provides protocols for monitoring of the battery charging and charger status from a remote location. |

| Configurable PWM (pulse width modulation) outputs (4). | Provides output control flexibility with the option to enter user-defined curves. |

| Direct governor & AVR control. | Eliminates the requirement for external control equipment. |

| Automatic and manual speed control. | Provides the user the option to manually raise the engine speed. |

| Clutch control. | Provides a gradual increase and decrease in speed as determined by the user. |

| CAN, magnetic pick-up or tachometer speed sensing. | Provides the option for engine speed monitoring, either for electronic or traditional non-electronic engines. |

| Remote communications (RS232, RS485, Ethernet). | Provides secure and simple off site monitoring. All ports are continuously active. |

| Data logging & trending. | Provides current and historical status information. |

| Configurable event log (250). | Provides access to historical alarms and operational status. |

| Integral PLC editor. | Ensures additional applications are easily integrated into the system. |

| DSE Configuration Suite PC Software. | Provides complete user-friendly configuration and easy-to-use high-level system control & monitoring. |

| Additional Features |

|---|

| – Multiple language options. | – Engine run time scheduler. | – Manual fuel pump control. | – SCADA monitoring. |

| – Power save mode. | – Charge alternator failure alarm. | – USB connectivity. | – Modbus RTU/TCP support. |

| – Configurable timers & alarms. | – Tier 4 CAN engine support. | – Automatic speed ramping. | SMS messaging start & stop functionality. |

| – Engine maintenance alarms (3). |

| DC Supply | INPUTS | OUTPUTS |

|---|---|---|

| CONTINUOUS VOLTAGE RATING 8 V to 35 V Continuous |

DIGITAL INPUTS A to K Configurable as: Positive switching Negative switching |

DC OUTPUT A (FUEL) & B (START) 10 A for 10 seconds, 5 A continuous at supply voltage |

| CRANKING DROPOUTS Able to survive 0 V for 50 mS, providing supply was at least 10 V before dropout and supply recovers to 5 V. This is achieved without the need for internal batteries. |

RATIOMETRIC INPUTS B to L Configurable as: Negative switching digital input 0 V to 10 V 4 mA to 20 mA 0 Ω to 1920 Ω |

VOLT-FREE OUTPUTS C & D 5 A DC at 35 V DC 8 A AC at 250 V AC |

| MAXIMUM OPERATING CURRENT 510 mA at 12 V, 238 mA at 24 V |

DC OUTPUTS E, F, G & H 2 A DC at supply voltage |

|

| MAXIMUM STANDBY CURRENT 226 mA at 12 V, 107 mA at 24 V |

PWM OUTPUTS I, J, K & L 4 A at supply voltage 20 Hz to 250 Hz |

|

| MAXIMUM OFF MODE CURRENT 180 mA at 12 V, 86 mA at 24 V |

||

| CHARGE FAIL/EXCITATION RANGE 0 V to 35 V |

| PULSE PICK-UP | BUILT-IN GOVERNOR CONTROL |

|---|---|

| VOLTAGE RANGE ±0.5 V to 60 V RMS Fully isolated |

MINIMUM LOAD IMPEDANCE 1000 Ω Fully isolated |

| FREQUENCY RANGE 10,000 Hz (max) |

GAIN VOLTAGE 0 V to 10 V DC |

| OFFSET VOLTAGE ±10 V DC |

| ELECTRO-MAGNETIC COMPATIBILITY | ELECTRICAL SAFETY | TEMPERATURE |

|---|---|---|

| BS EN 61000-6-2 EMC Generic Immunity Standard for the Industrial Environment. |

BS EN 60950 Safety of Information Technology Equipment, including Electrical Business Equipment. |

BS EN 60068-2-1 Ab/Ae Cold Test -30°C. |

| BS EN 61000-6-4 EMC Generic Emission Standard for the Industrial Environment. |

BS EN 60068-2-2 Bb/Be Dry Heat +70°C. |

| VIBRATION | HUMIDITY |

|---|---|

| BS EN 60068-2-6 Ten sweeps in each of three major axes. 5 Hz to 8 Hz @ +/-7.5 mm, 8 Hz to 500 Hz @ 2 gn. |

BS EN 60068-2-30 Db Damp Heat Cyclic 20/55° C @ 95% RH 48 Hours. |

| BS EN 60068-2-78 Cab Damp Heat Static 40° C @ 93% RH 48 Hours. |

| SHOCK | DEGREES OF PROTECTION PROVIDED BY ENCLOSURES |

|---|---|

| BS EN 60068-2-27 Three shocks in each of three major axes 15 gn in 11 ms. |

BS EN 60529 IP65 – Front of module when installed into the control panel with the optional sealing gasket. |